On a rare sunny day amid the heaviest snowfall in several years, we revisited the birthplace of DP Paper, several years since its development. The Shinano River, which connects to the Chikuma River that crosses the archipelago in the far distance, is an important water resource for this paper.

Water, an integral ingredient in paper

Like leather, paper needs the blessing of nature in the form of water, and there is nothing better than clean water. The source of the water used in the manufacturing process of DP Paper comes from the mountains of the Japanese Alps.

The Shinano River flows majestically next to the paper mill. The vast surface of the river is mesmerizing to watch after its long, long journey, and it seems as if the paper is gently rippling in the water. This river, the largest river in Japan, which brings us abundant and high-quality water, is the home of “DP PAPER”.

The perfect pulp recipe

In addition to water, the paper is made from pulp of wood chips. To develop a high-quality paper for refills that we, as writers, demand, another secret ingredient is the type of wood used.

There are not many papers in the world that can satisfy such desirable requirements as thinness, durability, smoothness, and resistance to bleed-through. The process of making such selfish paper began with increasing the pulp content of coniferous wood, which has long fibers.

However, it is not possible to simply increase the amount of pulp, which is one of the most difficult aspects of paper making. This is a bit technical, but softwood pulp with long fibers remains relatively long even after going through the beating process (pulp breaking into pieces), which is the preliminary stage of papermaking.

When paper is made from softwood pulp, the fibers are closely intertwined, making the paper strong and smooth. However, because the fibers are tightly packed together, ink cannot penetrate the paper properly, and ink does not dry easily after writing.

From this point on, it was a continuous process of trial and error to find the right balance between softwood pulp and hardwood pulp. The process of detailed testing continued to determine what would be the standard for “DP PAPER” – Thin, lightweight, strong, durable, no bleed-through, and easy to dry… we were aiming for an ideal paper for system organizers and for people who enjoy writing on paper.

The paper makers

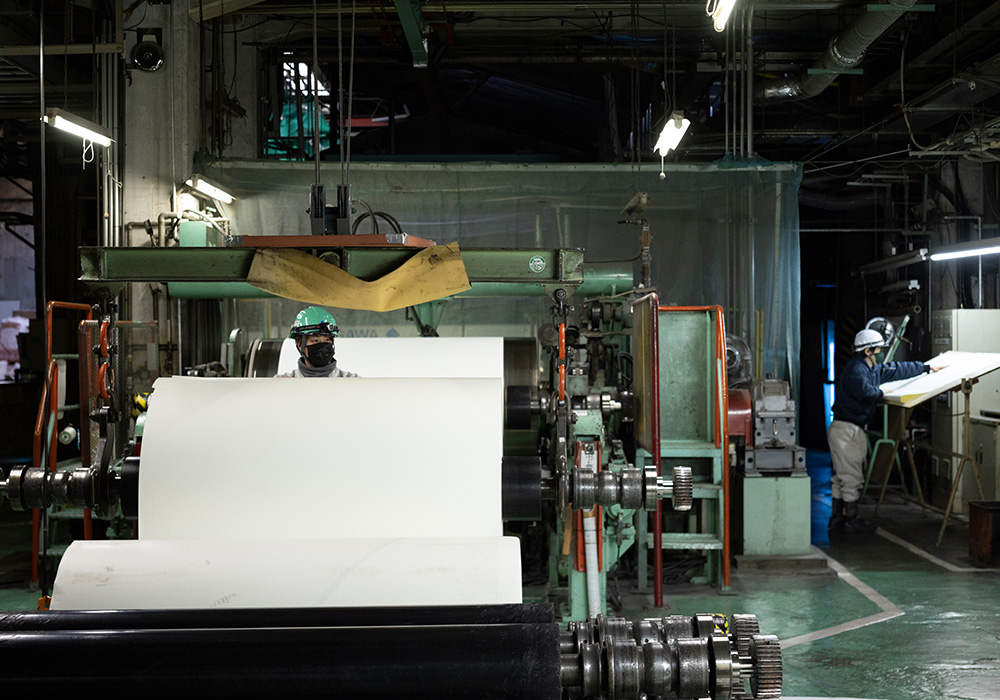

Once the recipe has been decided upon, the pulp is beaten, paper is made, dried, and rolled up, all in the blink of an eye. Yes, the mass production of paper is a huge and speedy process. After all, paper is made in batches—each batch produces the quantity equivalent to half a year’s worth of paper consumed by everyone at once.

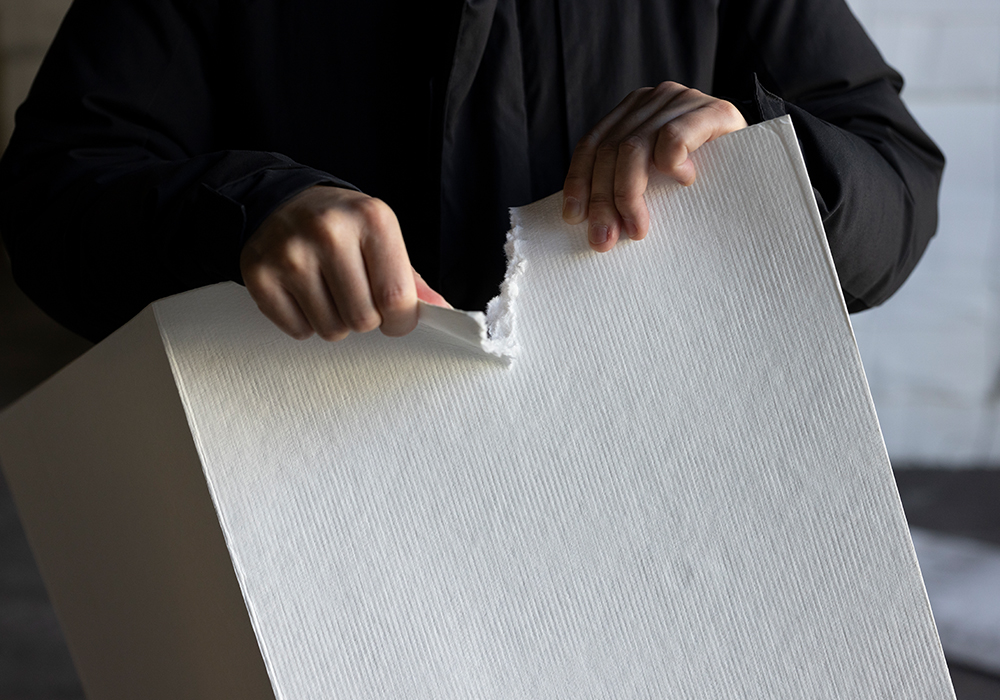

The papermaking process cannot be stopped in the middle of production, so the care that must be taken in the preliminary arrangements and quality checks is immeasurable. Although DP Paper now boasts stable quality, last-minute quality checks are still indispensable every time additional paper is made.

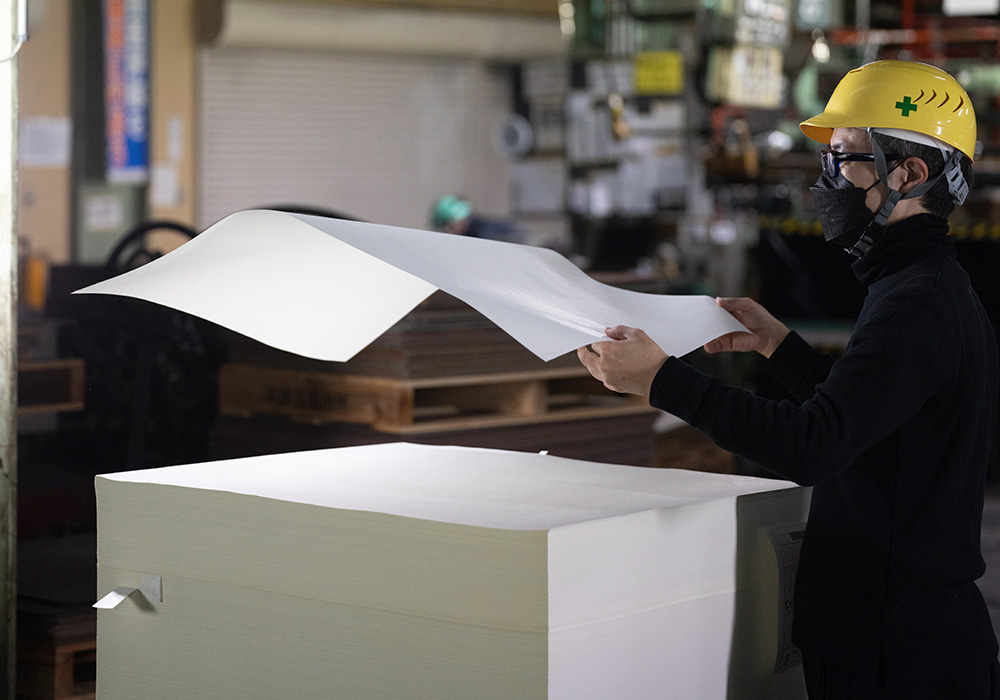

And of course, the writing test for each paper lot is still an important step. Even though it is an industrial product, to create a satisfactory “sheet”, the eyes and hands of the craftsman are firmly present at every step of the process. The analog world of manufacturing has been handed down from generation to generation, just like washi papermaking.

Each time we look at a complete refill, we feel deeply moved. The final product took shape thanks to the blessings of nature and the skills of so many people involved in the process.

The thickness of the stack of paper reminds us of the process and the craftsmen involved. The light reflection of the paper in the light, with a slight cream tint, is pleasing to the eye and stimulates the desire to write.

DP Paper is the original refill paper for ring-bound notebooks that condenses many stories of its making. We hope that each writer’s creativity will resonate across this sheet of paper.

Draw Today, Shape Tomorrow